|

|

~ TIPS & TRICKS TO ENHANCE YOUR MODELING SKILLS ~

Please be patient. Large photos loading. . . CORRECTING & ADJUSTING EARLY TOMALCO ® TURNOUTS

~ Updated Friday, February 06, 2009 ~

|

|

|

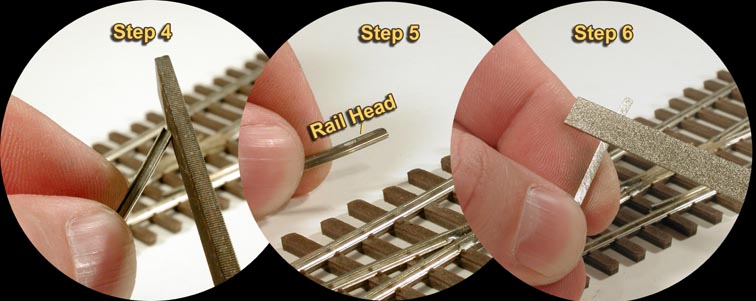

Here we've removed the guard rail and we're "dressing" it's ends with a mill

bastard file.

Reason for dressing it? We don't like leaving sharp edges on anything. We've suffered too many cut fingers ( and other appendages ) poking around under the hoods of cars to ever think of leaving something that's within our control to chance. |

In this photo you can see the results of our filing process. A nice, smooth,

rounded guardrail end that won't snag your finger ( ouch ! ) when you're running

that rag with track cleaner on it around before your next operating session.

[ An aside here is that I do this at each and every rail end / rail joint, for the same reasons noted above. I don't like cut fingers any more ! ] |

In this photo, we've just roughed up the bottom-side of the guard rail in

preparation to cementing it in place with Gap Filling ACC.

We're using one of those flexible "Diamond" files we sell ( PBL-806 ) 'cause they're rough enough to get the job done quickly. ACC just doesn't stick well to slippery surfaces. [ The ties themselves don't seem to require roughing up. ] |

Click here , or on the Icon above to proceed to the Tomalco Turnout Fix page Five !

Click Here

to return to Tomalco Turnout Fixes Page One.

|